summit sealproduct design, product development, & manufacturing

OVERVIEW

A variety of wine toppers designed with Andrew MacDonald and Kira Hughes for our third-year product design studio to sell at a local gift market on Pearl Street in downtown Boulder, Colorado.

Our vision started with the prompt of “Colorado love,” inspiring us to create a product that showcased Colorado while fostering community.

The wine toppers featured four of our original designs: topography from a local hike, an abstract peak formation, sunset over the Flatirons, and a geometric mountain form.

We produced these in two material mixtures: repurposed wood, and a concrete mixture of Rockite, quick-setting cement, crushed up wine bottles, fritz, and sand from the Boulder Creek.

BACKSTORY

While this is the product we brought to market, we actually spent most of the semester working on a wine holder and chiller, which entailed the same concrete mixture and rubber molding process, only at a much larger scale.

We designed and developed this wine chiller— the Aprés Chill— from September until we finally had to pivot on the Tuesday before our Saturday market.

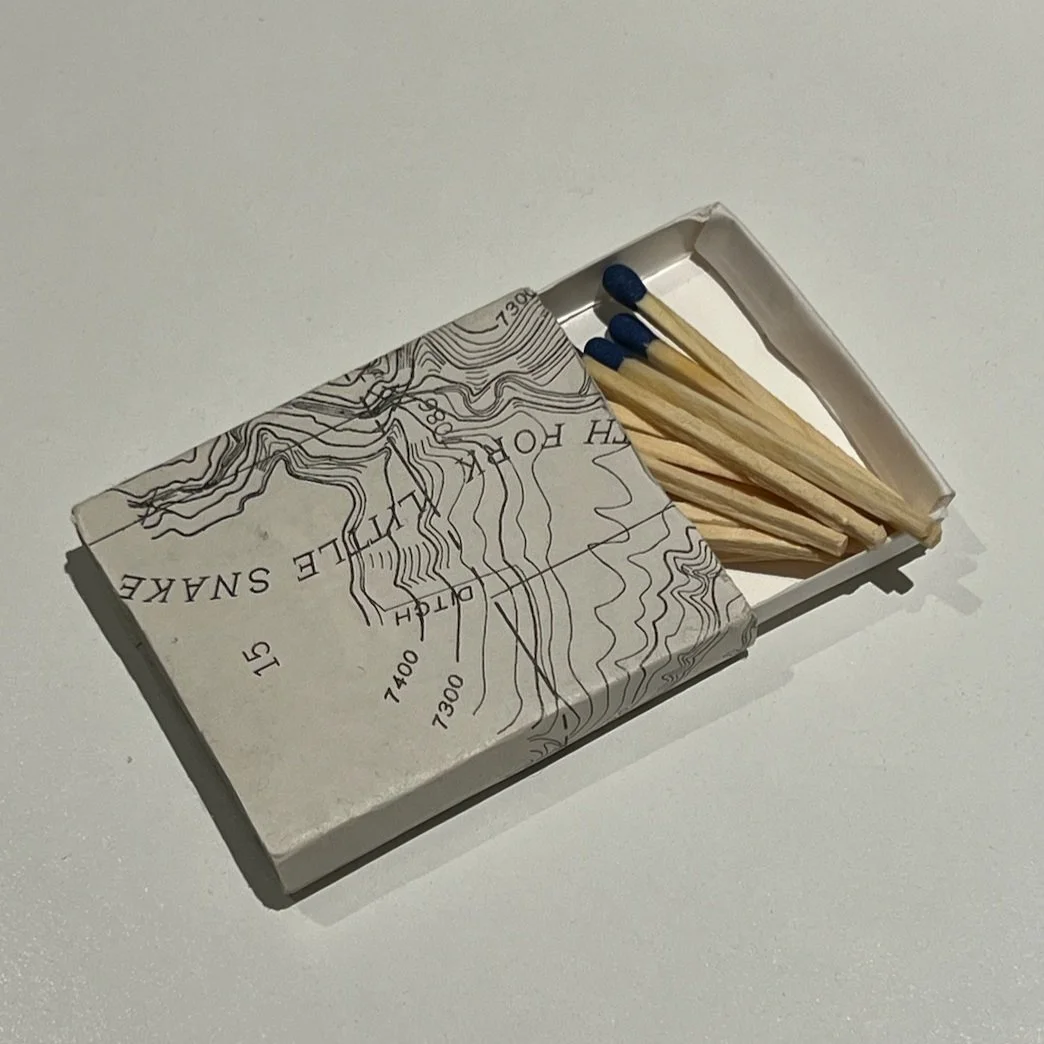

In those crucial four days following, we managed to 3D render four new designs all representing Colorado in various ways, 3D printed these and used them to make rubber molds, poured and pulled several rounds of concrete as well as using a CNC machine to print the designs into repurposed wood, assemble and sand each, and create new packaging in Rhino which we laser cut into repurposed wood for cohesive materiality.

By that Friday we had successfully produced a total of 32 wine toppers, which were the first product to sell out at market!

The smaller scale entailed a lower price point and ended up being perfect to market as stocking stuffers, which allowed our product to sell quickly and be more successful than the Aprés Chill would’ve probably been. We learned so much from all of our efforts with the first idea, that we were so familiar with the process by the time we had to pivot that the second try went incredibly smoothly.

Of course, after market was over, we went back to the first idea which we were all still so invested in, and worked to successfully get 5 finished wine chillers out of the mold in tact!

So, in the end, we technically came out with not only one, but two finished product ideas — Summit Seal AND Aprés Chill, both perfect to enjoy with a side of wine.

Since our design process had so many twists and turns, here’s a deep dive into our design process from start to finish, product to product…

IDEATION STAGE

Inspired by the theme “Colorado love,” we decided to focus on community and potentially hosting with an elegant twist, in order to appeal to the majority of Boulder residents.

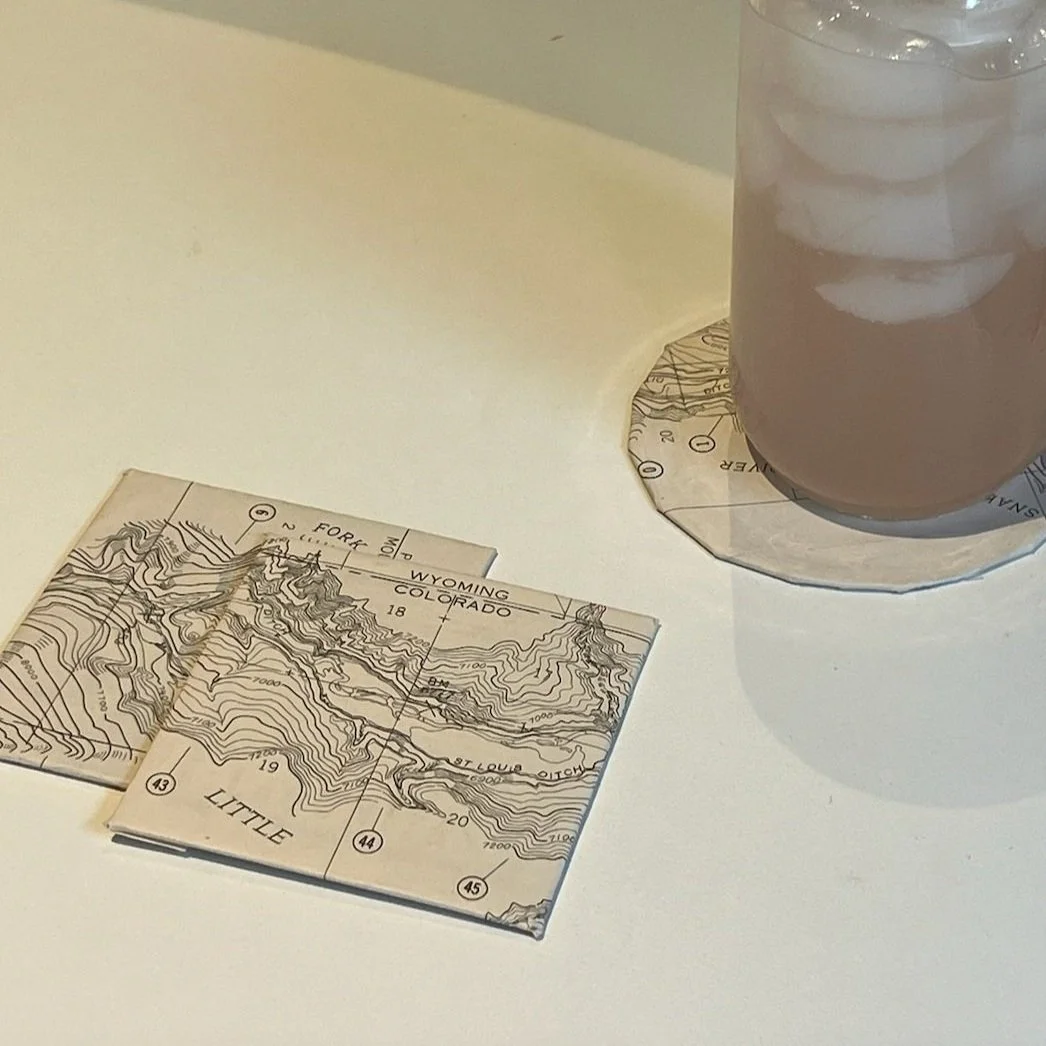

I thought incorporating a vintage topography map of nearby mountains could be a visually aesthetic way to follow our theme. Another way I explored was creating an illustration of the Flatirons— an easily-recognizable, well-loved mountain range in Boulder. I created the design on Illustrator first so that I could put each aspect onto layers, and printed them to put individually. I traced these forms on various shades of warm-toned construction paper, layered them and added lamination. I wrapped this around a circular base to create a candle holder, also shown on the right.

Colorado has such beautiful sunsets, and Flatirons are a perfect, popular spot to watch them, which I wanted to represent in this design through color.

LOW FIDELITY PROTOTYPES

designed by me

JEWELRY or TRINKET “CO” TRAYS

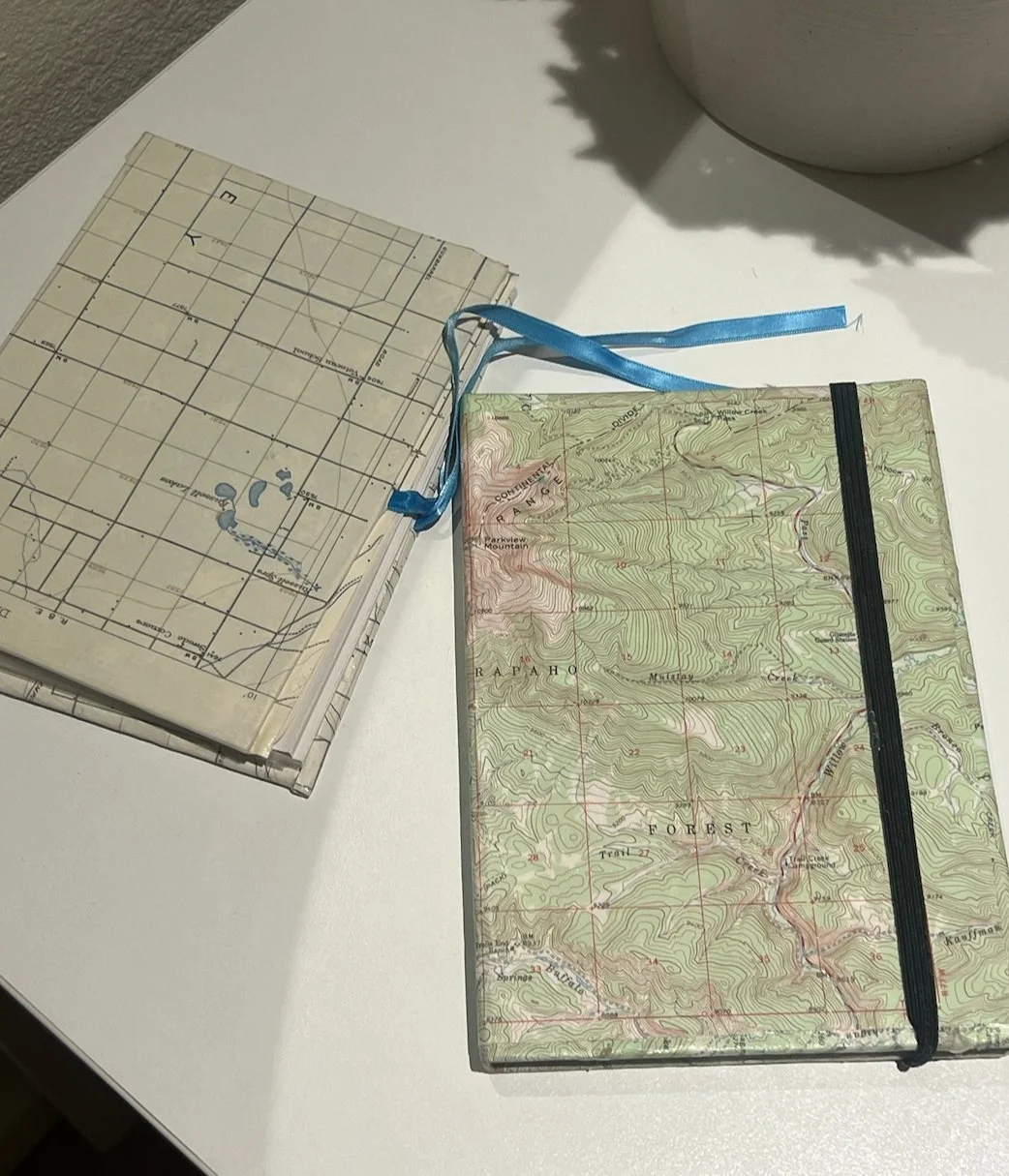

JOURNALS + NOTEBOOKS

CANDLE HOLDER front

& side view

DESIGN PROCESS

The moment I pitched the idea of a wine holder and potentially wine chiller, it was an immediate favorite. This perfectly encapsulates hosting and gathering community, and can easily be morphed into a representation of Colorado.

Andrew and I hadn’t worked with molds before and were eager to, so we decided to go with this as our manufacturing process. We knew the material would have to be able to keep liquid cold and be able to survive the freezer without deteriorating. Upon further research, we discovered that a concrete and cement mixture would do both of these things, and work perfectly with our molding idea.

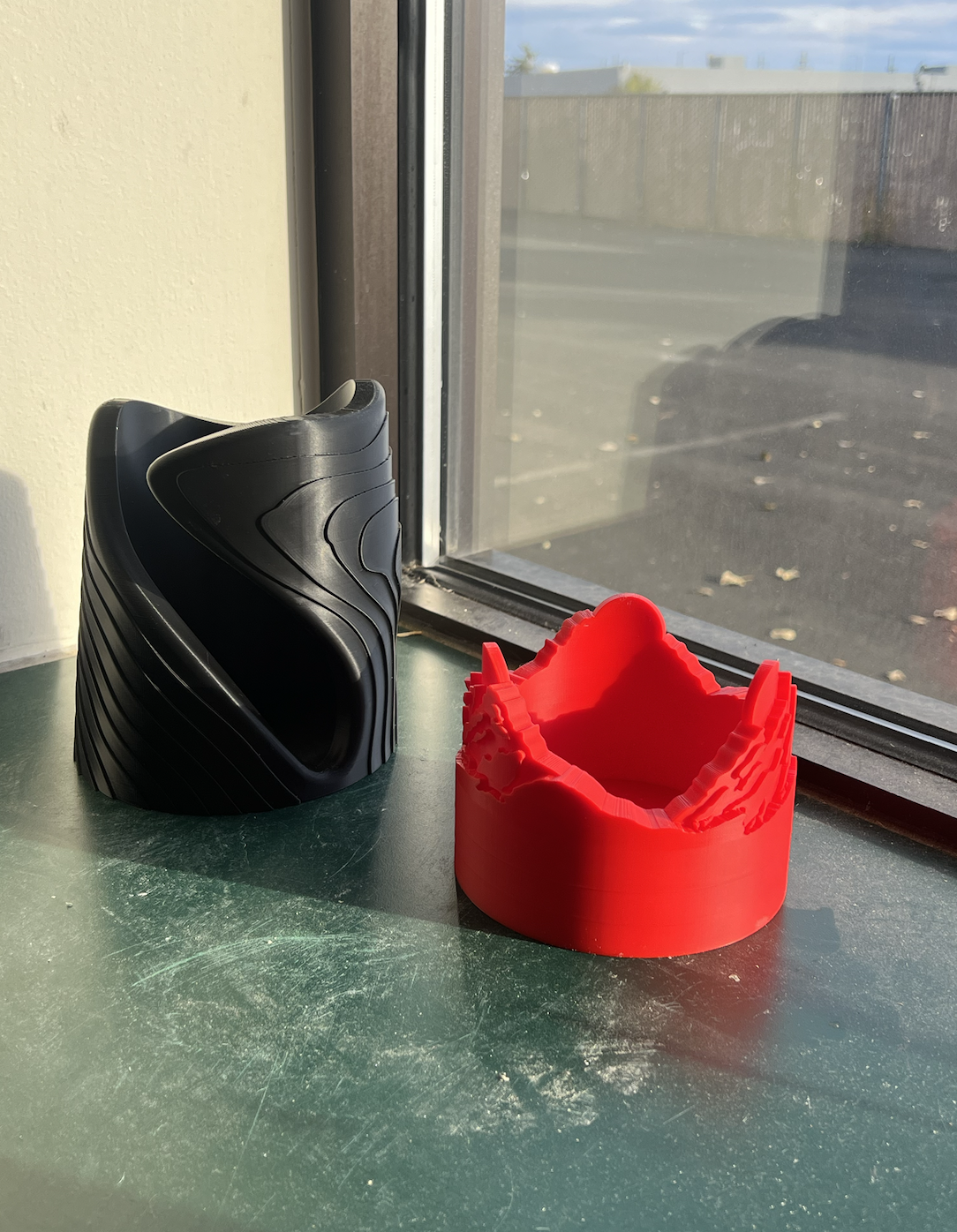

Once we decided on a wine chiller, we experimented with different ways to aesthetically represent the mountains both topographically and in abstract peak formations. The goal was to create a wine chiller in a more evolved shape, as most are a simple, cylindrical form. We started these as low fidelity prototypes using materials like paper and cardboard, then moved to clay, and finally 3D rendered each design on Rhino to be 3D printed for final comparison.

This left us with two intricate designs: one more abstract with elevated topography, and one a more literal depiction of a well-loved aspect of Boulder. Ultimately, we decided on the more abstract topographic prototype, as it fit better with the elegant, natural, monochromatic look.

COASTERS

MATCHBOXES

THE EVOLUTION OF OUR TOPOGRAPHIC DESIGN

MATERIALS + MANUFACTURING

This is where the difficulty began…

We wanted our product to be as sustainable as possible, and find a way for our materiality to incorporate elements from our design concept into its physical form. These ended up being crushed up wine bottles, and sand from the Boulder creek— another local staple.

Our base went from cement to quick-setting cement to rockite, the most successful being a combination of the last two. At first, we tried adding shredded plastic cups too, but they made the material come out rough and unfinished when dry. We also experimented with the amount of sand and glass we were adding. With too much sand, the mixture dried grainy and crumbling.

A later addition was Fritz, another type of finely crushed glass. We ended up switching from wine bottles to Topo Chico bottles for a smoother finish.

A SIDE-BY-SIDE COMPARISON OF COMPLICATIONS SHOWN IN VARIOUS MATERIAL MIXTURE RESULTS

ROADBLOCKED

Unfortunately, some of the material mixtures we made weren’t strong enough to survive the mold, specifically the opening in the design. Using a 3D printed version of the form and polyurethane rubber, we poured multiple molds to cut in different ways to figure out the most efficient way to gently pull the cement form out of the mold. These attempts included cutting one mold in half, one mold in thirds, one in quarters, one with two straight cuts and one cut right along the curve, etc., yet each time at least part of the product would break, and the whole mold would usually be completely cut up and not always salvageable.

All of this was a huge roadblock, especially considering we only had a few weeks for the production stage and already were having to wait a minimum of 24 hours per product for the cement mixture to dry, not to mention how long the time and expense of making a new mold nearly every time. However, we were so close to success and had all become so invested at this point that we couldn’t give up until we knew we’d tried everything we could.

We finally got one out successfully on the Tuesday before our Saturday market, but between the time constraint and probability of each following to come out in one piece, we decided it would be in our best interest to pivot. Luckily, we managed to get a total of 4 out successfully, and glue one together well enough that, after much sanding, is now hard to tell apart from the others. Although it would’ve been fun to sell these at market like we originally planned, we each still got to take an Aprés Chill home with us, which felt like a success after all our efforts.

A QUICK PIVOT

APRÉS CHILL - THE FINAL WINE CHILLER PROTOTYPE

Fall 2024

Boulder, Colorado